Intel Malaysia: From a muddy paddy field to a manufacturing powerhouse

KUALA LUMPUR, Oct 20 — It’s the first time I’ve been to Penang since I was a child probably. Having grown up in Ipoh, I seldom found the time or need to head up north; it’s not like the food there is better than Ipoh anyway.

Nevertheless, it’s late August and I somehow ended up here on the island just a few weeks before Intel would go on to fully debut their new Meteor Lake architecture to the world. Well actually, I do know how I ended up here; Intel was about to give me and a number of other media folk from all over the world a tour of their facilities in Penang and nearby Kulim, Kedah.

Humble beginnings

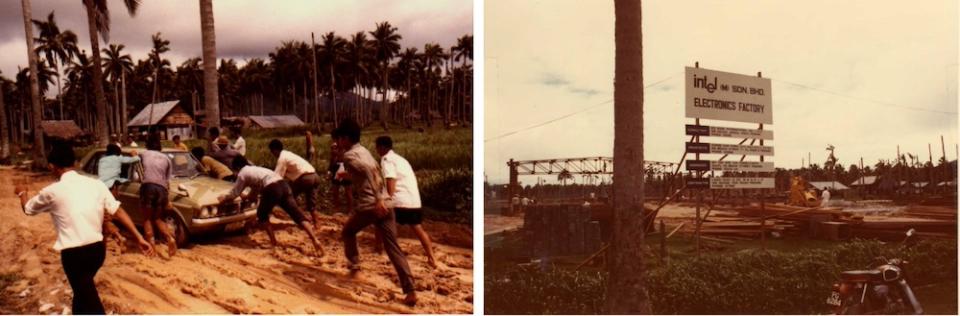

Intel has a storied history in Malaysia. The company first set foot in Malaysia over five decades ago in 1972, when they invested US$1.6 million to build the A1 plant, their first assembly plant in Penang as well as their first ever international manufacturing facility. It was built on top of what was just a muddy paddy field before that, and famously was also where the car of Intel’s then vice president Keith Thomson and future Intel CEO Andy Grove would get stuck after visiting the Penang plant during the monsoon season.

That first A1 Intel Malaysia site no longer exists. On 1 May 1975, a fire broke out in the three-year-old campus, with the suspect being a faulty light. It would only be an hour before the factory completely burned down to the ground, with only the cafeteria left standing. There were luckily no injuries reported as A1 was closed that day, but the fire would cause US$2.5 million in damage and it wouldn’t be till 1976 that production resumed at Penang.

Fifty-one years later though, I now stand in Intel Malaysia’s Penang campus, with the red (or rather, blue) carpets rolled out for us. There’s no facade of grandeur here though; every one of us on this tour of Intel’s facilities had to hand over our phones, laptops, cameras and so forth — we weren’t even allowed a pen and paper as we walked the factory floor. Such is the secrecy needed to ensure Intel’s production lines keep running and that confidential information stay classified.

Intel Malaysia’s double duty (and more)

Intel Malaysia started off as an assembly plant, which was very much seen as a win-win situation during the 70s, with Intel seeking lower costs while the Malaysian government was keen for a major name like Intel to rock up and create jobs here.

These days though, things have changed quite drastically. Intel Malaysia still isn’t quite where you’ll find Intel’s semiconductor wafers being fabbed, but their campuses here play a crucial role in Intel’s global manufacturing network — a marked shift from the original A1 plant that originally assembled just the 1103 DRAM integrated circuit. It has wafer fabs all around the world that create those shiny circular disks you’re probably familiar with, which then get sent to Intel’s Malaysia campuses, both in Kulim and in Penang.

The wafers will first arrive at the Kulim campus, where the Kulim Die Sort and Die Preparation (KMDSDP) in located. Here, we walked into the factory floor with laboratory coats and hair nets on us to find a place that was covered in this yellowish sepia lighting. There’s a reason for this of course, with the yellow lighting necessary to avoid the Mylar polyester sheet that holds these circular wafers in place from degrading.

The wafers are placed onto these Mylar sheets, and inserted into a machine that first etches out the actual dies themselves. They then get transported to another machine, which has powerful, watercooled saw blades slicing up the circular wafer disk into multiple little rectangles. A curious little robot arm then picks up each little die off the Mylar sheet and arranges them all onto a tape reel, almost like how a film roll is packed.

That’s just all the die preparation. The next stage at the Kulim facility is die sorting, where you’ll find huge machines stacked in rows, each housing 20 test cells that test each chip for defects, ensuring they’re up to spec. The die sorting side of the Kulim facility was also where we stumbled upon these curious little blue robots. They’re automated guided vehicles that collect a stack of dies from storage and automatically sends them over to the testing machines. Each of them play this little musical jingle, which lets the humans around know when they’re approaching. Try and block their way though and they’ll stop in its path, preventing any catastrophic accidents from happening.

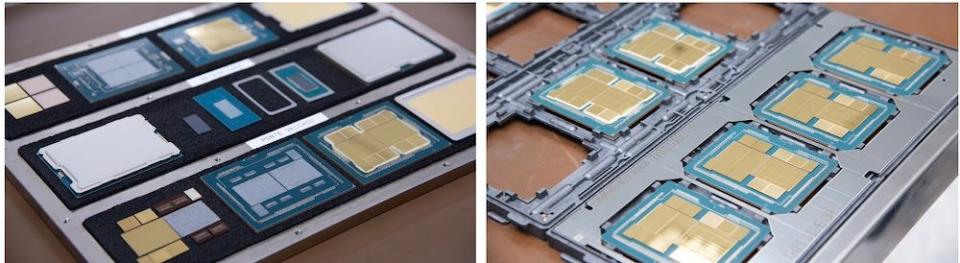

Once all that is done, the processed dies get sent across the Penang Straight to Intel’s Penang Assembly and Test (PGAT) facility for further processing. Here, the dies are bound to the teal-coloured PCBs that you’ll see on the edges of your desktop processor, with some epoxy placed between them to ensure stress is uniformly distributed across the die. They then place a little bit of thermal interface material over the die, before an integrated heat spreader is placed over it; this is usually only for their desktop and server processors as mobile processors don’t come with an IHS over the die.

These chips are basically done now, but still require a fair bit of testing before it can actually be packaged and sold to the consumer. The finished CPU gets loaded onto trays for a burn-in test, which stresses the chips at both high temperatures and high voltages in a bid to flush out the bad chips. Those that make it past the burn-in stage then get another round of tests, checking each chip’s electrical traces and functionality to ensure they work as intended, with a final platform performance verification stage which places these fresh processors into machines similar to the ones you and I would have to mimic real world conditions.

And lastly, Intel Malaysia is also host to their own System Integration and Manufacturing Services (SIMS) facility. Due to how vertically integrated Intel is, the company needs to make some very, very specialised equipment for itself; it’s not like you can just go onto Shopee and look for a High Density Burn-In Tester machine that lets you do burn-in testing on still-unreleased processors. SIMS is very much a one-of-a-kind factory. Rather than being directly involved in making Intel’s processors, it instead makes the kind of testing equipment such as specialist motherboards and machines needed to validate all the chips that come out of not just Intel Malaysia, but all of their facilities around the world.

Some of the key equipment that they manufacture themselves at the SIMS facility include the High Density Burn-In Tester that lets Intel perform burn-in testing, a High Density Modular Tester that lets them perform class and backend testing on their CPUs as well as System Level Testers used to validate the functionality of Intel products in real world environments.

And that won’t be all either. In late 2021, Intel announced a RM30 billion investment into their Malaysia site. Called the Pelican Project, this is set to be a new advanced packaging facility, and is set to go into operation some time next year and will be where some of the Meteor Lake mobile processors will be produced. Another assembly test site called Falcon is currently being built at the Kulim campus too. It’s all part of Intel’s plan to get back to the top with their oft-repeated goal of five nodes in four years.

People here seem to genuinely love their jobs

One thing that I truly couldn’t get off of my head though is that, during my couple of days walking through Intel Malaysia’s facilities, pretty much every single Intel employee we spoke to loved their job. Of course, it would make sense that Intel would perhaps cherry pick their most enthusiastic members of staff to talk to us, but it really did seem genuine even when we went off topic at times.

Whenever we asked members of staff how long they had been at Intel Malaysia, it was oftentimes over a decade with the shortest tenure we encountered being four years, a fresh-faced assistant to a veteran technician who had been there for nearly two decades. There were plenty of employees here with faded badges too, a sign that they have been year for long. One engineer even mentioned that he had spent over three decades working there, bar a couple of years in the middle when he left Intel, only to rejoin the company a few years later.

There were also plenty of women among the staff there, with Intel claiming 40% of their 15,000 workforce being women. Perhaps it starts from the top, with AK Chong currently Intel Malaysia’s managing director and the first woman to hold that position. She herself had been with Intel Malaysia for decades, having joined the company back in 1991, holding a number of different technical leadership roles before rising up the ranks.

Malaysia is very much a sentimental location for Intel too, with talk about how Malaysia in particular is a major site for Intel due to it being the location of their first international site, and they even claim that 98% of all employees at Intel Malaysia are Malaysian. They spend about USD330 million per year on local suppliers, and are on route to having invested about USD14 billion into the Malaysian economy by the time 2032 rolls around. Intel Malaysia wasn’t shy in talking about their efforts to give back to the community either, highlighting several programs that they run here such as the Intel Geek Kids initiative that goes around schools nationwide to have science workshops for underserved primary school kids.

From that tiny A1 plant in the middle of a paddy field, to a mega site encompassing 7 million sqft, 16 buildings and over 2 million sqft of manufacturing space, Intel Malaysia has grown probably beyond what Andy Grove could’ve ever imagined all those years ago when his car got stuck in the Penang mud. — SoyaCincau